CONTENTS

INTRODUCTION

MAL PAKISTAN LUBRICANT LTD

Product & Services

Why Synthetics

Army Welfare Trust

PROCEDURE AND CONDITIONS

CONDITIONS GOVERING THE

CONSTRUCTION AND OPERATING OF LUBRICATING OIL BLENDING/RECYLING PLANTS

MAL Pakistan Future

Plans...

BLENDING

(I.L.B)

Equipment

Process

control

Types of lubricants:

ADDITIVES

USED IN I.L.B

INTRODUCTION TO BASE OILS:

CONSTRUCTION OF STORAGE TANK

Jiskoot Technical Papers

a)

Crude Oil Blending -

b)

Lube Oil Blending

–An Overview for Lube Plants

c)

In-line Blending Systems

d)

In-Line Blending

(Control Systems)

e)

In-Line Lube Oil

Dehydration

Management of Petroleum Storage Tanks

LUBE OIL RECONCILIATION KEYS to control losses…

INTRODUCTION

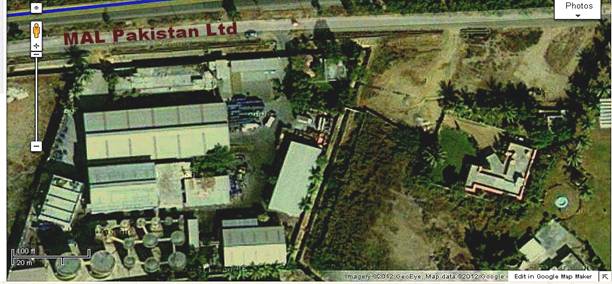

MAL Pakistan Limited is

the exclusive marketer of MOBIL Lubricants in Pakistan.

The MOBIL brand first entered Pakistan in September 1997 with its

world-renowned range of lubricants for automotive and industrial use. Business

is conducted through our corporate office located in Karachi,

regional offices located in Lahore and Islamabad and our state-of-the-art Lube Oil Blending Plant

situated in Hub, Baluchistan.

All our locally manufactured products undergo rigorous

quality control and testing at our laboratory situated inside the Lube Oil

Blending Plant. This has led to a virtually complaint-free reputation in the

market, even in the most severe applications. Specialized products not

manufactured locally are imported from our refinery at Jurong Singapore.

We have an extensive sales network throughout Pakistan

supplying lubricants to a

wide range of automotive and

industrial users. We have direct and indirect sales presence throughout the country including Karachi, Hyderabad, Sukkur,

Rahimyar Khan, Quetta,

Khuzdar, Gwadar, Sahiwal, Sargodha, Multan, Faisalabad, Islamabad and Peshawar,

giving us a truly nation-wide coverage.

Our automotive range includes passenger vehicle oils,

commercial vehicle oils, transmission oils, brake fluids and greases. Apart

from this, we are market leaders in high performance synthetic oils which are

being used in a majority of premium class and luxury vehicles across the

country.

For industrial applications, we have a broad product range

including gas engine oils, heavy duty diesel engine oils, turbine oils,

compressor oils, industrial gear oils and hydraulic oils. Our industrial

lubricants are being used in almost every industrial application around the

world and are endorsed by major equipment manufacturers globally. Segments

where our lubricants are market leaders

include; Power Generation, Chemicals , Oil

& Gas exploration , Textiles ,

Manufacturing, Construction, Marin

MAL PAKISTAN LUBRICANT LTD

Insight of LBSP for as a society member.

MAL Pakistan Ltd (formerly Mobil Askari Lubricants Ltd) was

registered in Pakistan

under the Companies Ordinance in December 29, 1996.

The Company was a joint venture of ExxonMobil Corporation.

In September, 2007, under ExxonMobil Corporation’s Global Distribution

Framework Model, the stake holders of the Company changed the Company’s name to

MAL Pakistan Ltd. and subsequent to that the Army Welfare Trust took over the

ownership of the Company.

ExxonMobil Corporation, is the largest Oil Company in the

world, operating in over 200 countries. ExxonMobil is a leader in almost every

aspect of the worldwide petroleum and petrochemical business. The Army Welfare

Trust, established in 1972, has wide ranging investments in banking, leasing,

insurance, cement, sugar, pharmaceutical business and real estates.

MAL Pakistan Ltd continues business as usual and is the

exclusive marketer of Mobil branded lubricants and coolants developed by Mobil

for its global accounts in Pakistan

under stewardship of ExxonMobil Asia pacific region.

For over a century Mobil has been an innovator in

lubrication technology and has manufactured breakthrough lubricants for

automotive, commercial and industrial sectors. These world-renowned Mobil

branded products, were launched in the country in September 1997. The Company

is the sole authorized importer and distributor of Mobil and Esso branded

flagship and synthetic products in Pakistan.

The Company’s Corporate Office is located in Karachi, with a Regional Office in Lahore

and Islamabad.

The Company’s Lube Oil Blending Plant, situated in Hub Baluchistan, is

a-state-of-the-art Plant as per ExxonMobil’s global standard.

In Pakistan,

the Company continuously strives to achieve superior financial and operating

results, while adhering to the highest standards of business conduct. MAL

Pakistan Ltd’s development & employment of local resources / talent, and

its extensive operational, technical, marketing guidance and training express

the Company’s commitment to Pakistan.

Product & Services

Industrial

Grades

|

Passenger

Vehicle Grades

|

Gas Engine

Oils

|

Petrol Engine

Oils

|

MOBIL Pegasus 1 Synthetic

MOBIL Pegasus 1005

MOBIL Pegasus 905

MOBIL Pegasus 805

MOBIL Pegasus 710

|

MOBIL 1 Synthetic

MOBIL Super XHP Plus 20W50

MOBIL Oil Super 20W50

MOBIL Oil Special 20W50

|

Turbine Oils

& Circulation Oils

|

Diesel Engine

Grades

|

MOBIL SHC 800 Series Synthetic

MOBIL DTE 800 Series

MOBIL DTE 700 Series

MOBIL DTE Named Series

|

Diesel Engine Oils

MOBIL Delvac 1 Synthetic

MOBIL Delvac MX 15W40

MOBIL Delvac Super 15W40 and 20W50

MOBIL Delvac 1330, 1340, 1350

MOBIL Delvac Special 20W50

MOBIL Delvac 1130, 1140, 1150

MOBIL 950

|

Gear Oils

|

4 Stroke

Motorcycle Oil

|

MOBIL SHC 600 Series Synthetic

MOBILgear 600 Series

|

MOBIL Special 4-T 20W50

|

Compressor

Oils

|

Automatic

Transmission Fluid

|

MOBIL Rarus 800 Series Synthetic

MOBIL Rarus 400 Series

|

MOBIL ATF 220

|

Greases

|

Brake Oil

|

MOBIL Askari Grease EP0, EP1, EP2

MOBIL Askari Grease 2

MOBIL Askari Grease 3

MOBILgrease XHP 222

|

MOBIL Universal Brake Fluid DOT 4

|

Furnace

Engine Oils

|

Automotive

Gear Oils

|

MOBILgard 412

MOBILgard M430

MOBILgard M440

|

MOBILube GX 80W90

MOBILube GX 140

MOBILube HD 80W90

MOBILube HD 85W140

|

Hydraulic Oils

|

|

MOBIL DTE 20 Series

Hydraulic AW Series

|

|

Heat Transfer Oils

|

|

MOBILtherm 603 and 605

|

Why

Synthetics

Synthetic motor oils can provide a variety of benefits that

help keep your engine running at optimal performance for years to come.

To understand synthetic motor oils, let’s look first at the

origins of all motor oils.

Conventional oils come from crude oil that is pumped from

the ground. Crude oil is made up of a complex mixture of molecules that form

chains and rings of different sizes and shapes. Long chains of carbon atoms

produce a thick, viscous fluid that flows slowly. Shorter chains produce fluid

that flows more readily.

In an oil refinery, crude oil is separated into various

fractions. These become the basis for lubricating oils and fuels. Thick tangled

masses of carbon chains become asphaltic materials used in roofing tar and road

work. Very short chains and ring compounds of carbon are volatile and can be

refined to produce gasoline and other products.

While petroleum refining is an advanced science, small

amounts of contaminants, such as sulfur and reactive hydrocarbons, cannot be

completely removed from petroleum, and may end up in motor oil base stocks.

All motor oils are made up of base oils and additives. In

general, fully synthetic motor oils contain non-conventional, high-performance

fluids. Synthetic blends usually use some non-conventional, high-performance

fluids in combination with conventional oil.

To meet the

demanding requirements of today's specifications (and our customers'

expectations), MOBIL 1® uses high-performance fluids, including

polyalphaolefins (PAOs), along with a proprietary system of additives. Each MOBIL

1 viscosity grade uses a unique combination of synthetic fluids and selected

additives in order to tailor the viscosity grade to its specific application.

Nomenclature

MAL Mobil

Askari Lubricants

API American

Petroleum Institute

ASTM American

Society for Testing and Materials

SAE Society

of Automotive Engineers

NHVI Number

High Viscosity Index

MVI Medium

Viscosity Index

BSHVI Base

Stock High Viscosity Index

|

An Overview to….

Army

Welfare Trust

Askari group of business

enterprises

MAL Pakistan Ltd: A joint venture

of AWT

A Culture of Excellence- A Tradition of Trust

AWT started with a modest asset base and high ambitions.

Today, after 39 years of investments in various fields, we stand at a dazzling

height of success and glory. Ours is a story of perseverance, innovation,

business acumen and going beyond the frontiers in Banking, Cement, Insurance, Aviation,

CNG, Agriculture, Manufacturing, Sugar, Security Solutions, Real Estate,

Lubricants, Defence Procurement and Trading and many other diverse fields. Our

investments will go a long way in consolidating the national economy of Pakistan.

HISTORY

Milestones in the History of AWT

Year of Operation Company/Business

Unit

1971 Army

Welfare Trust.

1972 Stud

Farm Probyanabad and Army Farm Rakh Baikunth.

1984 Askari

Sugar Mills Badin.

1984 Stud

Farm Boyalgunj.

1990 Askari

Real Estate Unit.

1990 Askari

Woolen Mills and Askari Shoe Projects.

1990 Blue

Lagoon & Army Welfare Mess.

1992 Askari

Bank Ltd.

1992 Fish

Farm.

1995 Askari

Aviation Pvt Ltd.

1995 Askari

General Insurance Company Ltd.

1996 Askari

Guards Pvt Ltd.

1996 Askari

Cement Plant Wah (acquired running).

1996 Mobil

Askari Lubricants Pakistan Ltd.

1997 Askari

Cement Nizampur.

2002 Askari

Compressed Natural Gas Project.

2004 Askari

Seeds.

2009 Askari

Enterprises Pvt Ltd.

VISION/MISSION

Vision

To be one of the leading business houses employing

best business practices.

Mission

To undertake safe and profitable commercial

activities in a manner that portrays AWT's image as a respected market leader

while generating maximum funds for meeting the welfare requirements of the

Army.

Core Values

We have an unwavering commitment of being a good

partner, focused on building productive, collaborative, trusting and beneficial

relationships with governments, other companies, customers, communities and

each other.

Business Units

Public Listed Companies

> Askari Bank Ltd

> Askari General Insurance Co Ltd

Public Unlisted Companies

> Askari Cement Ltd Wah

> MAL Pakistan Ltd

> Askari Securities Ltd

> Askari Investment Management Ltd

Private Limited Companies

> Askari Aviation Pvt Ltd

> Askari Guards Pvt Ltd

> Askari Enterprises Pvt Ltd

Other Business Units

> Askari Cement Nizampur

> Askari Real Estate

> Askari Projects (Woolen & Shoes)

> Askari CNG

> Askari Farms and Seeds

> Army Welfare Sugar Mills

> Blue Lagoon & Army Welfare Mess

> Askari Cement Marketing

> Askari Bank Ltd

> Askari General Insurance Co Ltd

Public Unlisted Companies

> Askari Cement Ltd Wah

> MAL Pakistan Ltd

> Askari Securities Ltd

> Askari Investment Management Ltd

Private Limited Companies

> Askari Aviation Pvt Ltd

> Askari Guards Pvt Ltd

> Askari Enterprises Pvt Ltd

Other Business Units

> Askari Cement Nizampur

> Askari Real Estate

> Askari Projects (Woolen & Shoes)

> Askari CNG

> Askari Farms and Seeds

> Army Welfare Sugar Mills

> Blue Lagoon & Army Welfare Mess

> Askari Cement Marketing

PROCEDURE AND CONDITIONS TO BE FULFILLED BEFORE THE GRANT OF

APPROVAL TO CONSTRUCT /MODIFY LUBRICATING OIL BLENDING/RECYCLING PLANT FOR THE

MANUFACTURE OF LUBE OIL

1.0 APPLICATION

PROCEDURE

Pursuant to the provisions of the Petroleum (Amendment)

regulations 1988, all applications for approval to construct/modify lubricating

oils blending/recycling plants, oil treatment plants, Petroleum Jelly and

Grease/Manufacturing Plants, shall be addressed to the Department of Petroleum

Resources Office, situated at 7 Kofo Abayomi Street, Victoria Island, Lagos

State, to be accompanied with the following documents as applicable:

Detailed description of the proposal stating clearly:

- Formulations, Specifications, Classifications, Grades, Trade Names and Identifications of the Products to be manufactured.

- Detailed description of laboratory facilities and equipment to be used for products quality control and test methods to be used.

- Proposals on effluent handling and disposal method Codes, Standards and Specifications to be adopted in the design of the plant with specifications of equipment and facilities to be installed.

- Two copies of the design drawings of the plant specifying the relative distances in meters between the plant and the adjoining properties.

- Two copies of piping and instrumentation diagram of the Blending/Recycling plant and sectional details of the storage tank.

- A certificate signed by the Chief Federal/State Fire Officer, or an Officer authorized by him in that behalf, that he is satisfied with the proposed arrangements for the prevention and containment of fire.

- A letter from the appropriate town Planning Authority, authorizing the sitting of the plant at the proposed site.

- A copy each of the Certificate of Incorporation, and Memorandum and Articles of Association of the company.

- A copy of the Company’s Current Tax Clearance Certificate covering the preceding three years.

- The prescribed application fee as from time to time determined by the Director of Petroleum Resources to be in the form of a bank draft made payable to the Federal Government of Nigeria-DPR Fees Account.

- A copy each of the Certificate of Registration of Trade Names and under which the company proposes to market the Lubricating oils (if different from that of the Blending Company).

- Required volume of Base Oils per year for blending the grades and classifications of Lubricating Oils applied for.

CONDITIONS

GOVERING THE CONSTRUCTION AND OPERATING OF LUBRICATING OIL BLENDING/RECYLING

PLANTS

2.1.0 CONSTRUCTION AND SPACING OF TANKS

For all strong tankers, the minimum distances shall be as

follows:

Between the perimeter of the tank and the outer boundary of

the installation, it shall be diameter of the tank or 25meters whichever is

greater.

Between two adjacent tanks, it shall be the diameter of the

smaller tank or 15meters whichever is greater.

STORAGE TANK DESIGN SPECIFICATION AND FITTINGS

All the storage tanks shall conform to the existing approved

standards of the Standards Organization of Nigeria, and is constructed from

mild steel or any other materials specially approved by the Director of

Petroleum Resources for peculiar reasons. They should be externally coated to

protect them from rusts and be conspicuously marked with their capacity either

in cubic meters or barrels as may be desired.

All the tanks shall be protected against atmospheric static

electricity discharges in accordance with the bright colors as approved by the

Department.

If they are to be exposed above ground, storage tanks shall

be painted in aluminum Grey or other bright colors as approved by the

Department.

When sited below the surface of the ground, they shall be

covered with a minimum earth thickness of 30.4cm with allowance made at surface

level for manhole covers.

If in the event of leakage, there is possibility of

contamination of underground water supplies, surface watercourses, or any

surface drainage system, the tanks shall be surrounded with puddle clay of not

less thank 3.48cm thickness or by fine concrete of a thickness approved by the

Director of Petroleum Resources.

When installed wholly or partly above the surface of the

ground, they shall be firmly supported with materials of structural integrity

to meet the approval of the Director and be surrounded with a retaining bund

wall that is large enough to contain 110% of the tank full contents.

In all cases, tanks shall

1.0 Be fitted with manholes of minimum diameter of 60.96cm

to facilitate easy access to the insides;

2.0 Be fitted with vents capable of relieving excess

pressure or vacuum;

3.0 Have access to their roofs by means of a ladder or

staircase constructed and attached to the outer tank shell

Armored cable shall be used for all electrical wiring.

Non-flammable materials shall be used for all constructions

within the plant.

All electrical lamp fittings shall be flameproof.

ENVIRONMENTAL PROTECTION

- All storage tanks shall be surrounded by bund walls constructed with concrete.

- The enclosure within the bund wall shall be capable of containing the whole contents of the full storage tank plus ten percent of the volume;

- There shall be adequate piping facilities for evacuating any liquids retained within the bund walls.

- There shall be installed in the enclosure, an efficient oil interceptor with an isolating valve leading to the drainage system;

- Water shall not be allowed to accumulate within the enclosure or any part thereof where the storage tanks are on concrete foundations and the bed of the enclosure is also of concrete, drainage of the enclosure shall be effected by means of a pipe fitted with a valve, to be kept close when not in use, and which is capable of being activated from outside the enclosure;

- The quality of the effluent generated from the drainage system in the plant shall be monitored at such intervals as specified in the existing environmental guidelines issued by the Department and shall be clearly entered in a register specifically kept for that purpose and monthly returns of these effluent analysis shall be rendered to the Department.

- All other precautions and provision of up-to-date equipment for preventing pollution as specified in the Ministry’s environmental guidelines shall be put in place to the satisfaction of the Director.

FIRE FIGHTING AND PROTECTION MEASURES

- In every lubricating oil blending or recycling plant, there shall be provided and kept in readiness to the satisfaction and approval of the Chief Federal/State Fire, Officer, adequate equipment for fire fighting and protection.

- Each item of fire fighting equipment shall be inspected and tested at appropriate intervals by a competent person appointed for the purpose by the licensee. The date of the last inspection shall be entered in a logbook kept for that purpose.

- All the personnel employed in the installation shall be instructed on the use of fire fighting equipment.

- Instruction to personnel in case of fire shall be clearly and concisely expressed in writing and prominently displayed at the site.

- "NO SMOKING" signs shall be conspicuously displayed at strategic locations in the plant and be illuminated for case of identification in dull brightness.

- Whenever a fire or any accident occurs in the installation a report of the circumstances and probable cause shall be forward to the Federal or relevant State Chief Fire Officer and to the nearest office of the Department by the Licensee within forty-eight hours of occurrence

- Automatic fail safe emergency alarm devices shall be incorporated in the critical sections of the plant.

- During operation, no storage tank shall be filled to more than 95% of its capacity.

- All maintenance requiring hot works on storage tanks shall be carried out under a permit issued by a competent person specifying detailed safety precautions that must be taken in the process.

QUALITY CONTROL

a) A

well equipped laboratory for quality control shall be established to test for

the following parameters using international test methods, (ASTM and IP), as

applicable to:

- Specific Gravity

- Flash Point

- Kinematics Viscosity

- Pour Point

- Viscosity Index

- Water Content

- Insoluble Content

- Acidity Level

- Total Base Number (TBN)

- Sulfated Ash Content (Trace metals Pb, Fe, Na, K, V, Ni, Co)

- Trace of PCB, PNA, depending on oil feedstock source (for lube used oil recycling)

All formulations and specifications of products to be

manufactured shall be forwarded to the Standards Organization of Nigeria for

consideration and approval.

b) Samples of all blended batches shall be retained for a

period of not less thank three months before disposal and be made available to

the Department on demand for any desired quality verification test within this

mandatory period of storage.

LICENSING PROCEDURE

Upon completion of the construction of blending or recycling

plaint, an application for license to operate the plant shall be forwarded to

the Department. The application shall be accompanied by the following;

i. Prescribed License Fee in bank draft payable to the

"Federal Government of Nigeria, DPR Fees Accounts"

ii. A photocopy of the approval obtained to construct the

plant

iii. A copy of the product formulations and specifications

approved from Standards Organization of Nigeria (SON).

iv. A copy of the third party blending agreement, (in case

of companies without plants), entered into with the blending company. The

agreement must have been cleared with the DPR and submitted in a legally

executed form.

v. Companies seeking third party blended arrangements shall

be required to submit evidence of ownership or management of licensed retailed

outlets or supply agreement to licensed end users.

vi. A copy of the product(s) trade name(s) registration with

the Federal Ministry’s of Trade.

vii. A final certificate of clearance signed by the Chief

Federal/State Fire Officer or any officer designated by him in that behalf,

that he is satisfied with the provisions for the prevention and containment of

fire.

viii. A set of plant operating manuals

A pre-commissioning inspection of the plant shall be carried

out on the satisfaction of the above listed conditions and a license to operate

the plant shall be granted on the satisfactory outcome of this confirmatory

plant inspection.

DEPARTMENT OF

PETROLEUM RESOURCES

APPLICATION FOR

LICENCE TO OPERATE LUBRICATING

OIL BLENDING PLANT

1. Name of Applicant/Company ………………………………………………………….

2. Registered Address in Nigeria ………………………………………… ………………

3. LOCATION DDRESS OF PLANT (Town, LGA, State) ………………………………

State Whether Application is for a New Licence or for

Renewal (Please Tick as Appropriate) If Renewal, Please Attach a Photocopy of

Expiring Licence

5. Storage Capacity of Base Oil………………………………………………….

Litres/kg

6. I/We Hereby certify that all the information Contained in

this form and the supporting Documents to the best of my/Our Knowledge are

correct.

Fee Paid: =N= …………………………………….…… ………………………………….

(In Figures) (In Words)……………………………………. ………………………………

Authorizing Company Signature Company Stamp and Date

(Bank Draft to be made payable to the Federal Republic of

Nigeria DPR Fees A/C)

………………………………………………………………………………..……………

(For DPR Use Only)

7. Bank Draft Reference Number …………………………………………………………

Amount ……………………………………………………………………………………

Receipt Number ………………………………………………………………………….

Name and Signature of Receiving Officer Date and Stamp………………………………

8. Recommendation of Processing Officer ………………………………………………..

……………………………………………………………………………………………..

Name and Signature of Processing Officer Date and Stamp………………………………

9. Licence Number ……..……Date Issued …..……Name and Signature

Date……..……

LUBE OIL BLENDING

PLANT CHECKLIST

*(print in capital letters only)

Field Office______________________ Identification Code________________________

Name of Company (as per Cert. Of Inc.)_______________________________________

Regd. Address: ___________________________________________________________

Location of Facility: ______________________________________________________

LPG_________________________ State_____________________________

Application type (New/Renewal/Takeover): ___Year of Expiration

of Previous Lce.____

FEES PAID…………………………… RECEIPT No……………………………………

RECEIPT ISSUE LOCATION……………… RECEIPT ISSUE DATE…….……..……

BANK DRAFT DETAILS……………………………………………………………......

LIST OF ATTACHED DOCUMENTS

|

YES

|

NO

|

N/A

|

|

1

|

CERTIFICATE OF INCORPORATION OF COMPANY

|

|||

2

|

APPROVAL TO CONSTRUCT/LETTER OF RELEASE

|

|||

3

|

APPLICATION FOR A LICENCE TO OPERATE

|

|||

4

|

APPROPRIATE PLANT PHOTOGRAPHS

|

|||

5

|

CERTIFIED TRUE COPY OF MEMORANDUM AND ARTICLE OF

ASSOCIATION

|

|||

6

|

FIRE REPORT

|

|||

7

|

CURRENT THREE YEAR TAX CLEARANCE CERTIFICATE

|

|||

8

|

EXPIRED LICENCE

|

|||

9

|

HYDROTEST CERTIFICATE

|

|||

10

|

APPROVED BUILDING PLAN

|

|||

11

|

EIA APPROVED REPORT

|

PRE-LICENCE PROVISION

|

YES

|

NO

|

N/A

|

|

1

|

ADEQUATE FIRE FIGHTING FACILITIES (FIXED & MOBILE)

|

|||

2

|

ADEQUATE SAFETY & OIL/CHEMICALS SPILL CONTAINMENT AND

CLEAN UP MATERIALS

|

|||

3

|

PERSONNEL PROTECTIVE WEARS FOR OPERATORS

|

|||

4

|

SECURITY CHECK POST

|

|||

5

|

POWER SOURCE underline type – SUUPLIED/GENERATED OR BOTH

|

|||

6

|

LIGHTNING AND EARTHING PROTECTIVE DEVICES

|

|||

7

|

EMERGENCY SHUTDOWN SYSTEM

|

|||

8

|

BUND WALLS CONSTRUCTED AS PER API, ETC STANDARD

|

|||

9

|

CORROSION PROTECTION DEVICES

|

|||

10

|

FIRE CLEARANCE ZONE OF MINIMUM 3 METRES AROUND THE

PERIMETER FENCE OF THE PLANT

|

|||

11

|

COLOUR CODING OF PIPE CONNECTIONS, HOSES, ETC

|

|||

12

|

MEDICAL FACILITIES/FIRST AID MEDICAL FACILITIES

|

|||

13

|

VEHICLES

PARK CONSTRUCTED

OUTSIDE THE PLANT

|

|||

14

|

LABORATORY FOR QUALITY CONTROL PURPOSES

|

|||

15

|

EMERGENCY RESPONSE ACTION PLANS CONSPICUOUSLY DISPLAYED

|

|||

16

|

BRICK WALL PERIMETER FENCE, GREATER THAN 1.5 METRES HIGH

|

|||

17

|

WATER STORAGE FACILITIES (FIRE FIGHTING & DRINKABLE)

|

Name of Plant Manager: ___________________No. of Trained

Attendants___________

Products

|

No. of Tank(s)

|

Capacity of Each Tank (M/Tons)

|

Vol. Applied for (M/T)

|

Approval to Construct by………………………………………... Date…………………..

Name of Inspector_______________________________ Date Inspected_____________

1. Are above inclusions adequate for issuance of

Permit/License? Yes/No

2. Recommendation_______________________________________________________

3. OPSCON’s Signature__________ Name____________________ Date____________

4. DPR HQ validation by___________________________ Date____________________

5. Downstream Remarks____________________________ Date___________________

BLENDING (I.L.B)

One Worker Multiple

Machine Layout (OWMM)

Lubricants and Additives blending units

Equipment

AUTOMATIC

BATCH BLENDING (ABB)

DRUM

DECANTING SYSTEM (DDS)

INLINE BLENDING (ILB)

In-line

blending is the process of mixing together a number of liquids to achieve a

finished product of closely defined quality and quantity.

A good

blending system should achieve this without the need for blend adjustments

(wastage), with sufficient automation to limit the potential for errors and

should keep the labour and production costs to a minimum.

Jiskoot and Cellier is an

internationally acknowledged leader in the field of in-line blending systems

with over 40 years experience of blender design. They can supply solutions

ranging from simple ratio control two-stream blenders for fuel and crude oil

applications through to large systems with automatic density or viscosity blend

optimization. Jiskoot and Cellier is able to provide complete blending

solutions from design to start-up and their systems are guaranteed to operate

as a totally integrated part of a process plant and reduce the operating costs.

§ Applications

A range of turnkey, integrated in-line blending systems for process liquids including crude oil, LPG, LNG, ethanol and bunker fuel oil.

A range of turnkey, integrated in-line blending systems for process liquids including crude oil, LPG, LNG, ethanol and bunker fuel oil.

§ Systems

fully guaranteed turnkey in-line blending systems. The system type depends on the products being blended, the quality of feedstock and the final product specifications.

fully guaranteed turnkey in-line blending systems. The system type depends on the products being blended, the quality of feedstock and the final product specifications.

§ Products

A range of control systems, analyzer loops and mixing systems that offer the optimum performance as part of an in-line blending system.

A range of control systems, analyzer loops and mixing systems that offer the optimum performance as part of an in-line blending system.

Process control

SYNOPTIC

DISPLAY

CONTROL SYSTEMS

InSpec Blender Controller

|

||

The InSpec blender controller is a true 3-term PID controller,

suitable for controlled rate batch blending, wild stream responsive blending

and analyzer trim applications.

|

||

PNEUMATIC CONTROL ROOM

Safe area

blender controller

|

||

The

InSight is a safe area real-time blender controller with an intuitive user

interface. Designed for 2-8 stream in-line blending applications, the InSight

can be used for ratio control, viscosity trim, and density trim or analyzer

trim blending systems. The InSight can be operated as a stand-alone

controller or integrated as part of a distributed control system (DCS).

§ Real-time

operating system (not PLC)

§ Self

learning algorithms to guarantee accuracy

§ Polynomial

meter linearisation for high accuracy blend control

§ Volume

or mass blending

§ Volume

correction to API 2540 and IP 200

§ Can

perform single product bulk loading with metering

§ Flow

weighted averages for control parameters

§ User

programmable logic

§ Ratio

or analyser control modes

|

||

MIXING SYSTEMS

Mixing at the outlet to a

blender header is crucial to ensure that the product delivered is fully

homogenous. Mixing becomes even more important if analyzers are mounted

in the blender header to provide quality optimization of the blended

products. Jiskoot and Cellier mixing systems are all designed in

accordance with international sampling standards to guarantee product

homogeneity.

|

Jet Mix mixer

|

||

The Jet Mix mixing system uses a pump to withdraw a small

portion of the process fluid and re-introduce it into the pipeline, in the

form of high velocity jets.

A Jet Mix has no pressure-drop and is suitable for high-turndown blenders where the pressure drop normally developed across a static mixer is unacceptable. The pumped bypass loop of a Jet Mix system can also be used for the installation of on-line analyzers such as densitometers to avoid the need for mounting insertion devices in the blender header. |

||

Static mixers

|

||

In

applications where there is a limited flow turn down, a static mixer may have

a sufficiently low pressure-drop and provide enough mixing at all flow rates

to be suitable for blenders. Static mixers supplied by Jiskoot and Cellier

are supported by pressure drop estimates.

|

||

ANALYSERS

Densitometers

|

||

Accurate density measurement is crucial to the quality

optimization of an in-line blender or custody transfer measurement system.

Jiskoot and Cellier has experience of the design and deployment of numerous

bypass loop density measurement systems for custody transfer and fiscal

applications. Jiskoot and Cellier has alliances with key manufacturers to

ensure transmitters are correctly installed and calibrated to optimize

performance.

|

||

Viscometers

|

||

Accurate viscosity measurement is crucial to the success of the

quality optimization of an in-line blender. Jiskoot and Cellier has developed

alliances with key manufacturers to ensure that transmitters are correctly

installed and calibrated to optimize performance in any application.

|

||

Types of lubricants:

- Automotive Lubricating Oil.

- Industrial Lubricating Oil.

INTRODUCTION TO

LUBRICANTS:

A lubricant is a substance

(usually a liquid) introduced between two moving surfaces to reduce the

friction and wear between them. A lubricant provides a protective film, which

allows for two touching surfaces to be separated, thus lessening the friction

between them. Lubricants are an essential part of modern machinery.

Lubricants are generally

composed of a majority of base oil (most often petroleum fractions, called

mineral oils) and a minority of additives (chemicals). Typically lubricants

contain 90% base oil and less than 10% additives.

PROPERTIES OF LUBRICANTS:

Lubricants perform the

following key functions.

- Keep moving parts apart.

- Reduce friction.

- Transfer heat.

- Carry away contaminants & debris.

- Transmit power.

- Protect against wear. (anti wear, extreme pressure)

- Reduce corrosion and rust.

- Seal for gases.

INTRODUCTION TO ADDITIVES:

Additives (chemicals) are

used with base oil to impart desirable characteristics of lubricating oil.

Additives are used for reduced friction and wear, increased viscosity, improved

viscosity index, resistance to corrosion and oxidation, aging or contamination,

etc. A large number of additives are used to impart performance characteristics

to the lubricants.

- Antioxidants. (zinc dithiophosphates)

- Viscosity index improvers. (polymethacrylates)

- Anti-wear. (zinc dialkyldithiophosphate)

- Pour point depressants. (co-polymer of methacrylates)

- Corrosion inhibitors ( alkaline compounds, esters)

- Rust inhibitors (alkaline compounds, organis acids)

- Friction modifiers (graphite, molybdenum disulfide)

- Extreme Pressure (chlorinated paraffins)

- Anti-foaming agents. (dimethyl silicones)

- Demulsifying / Emulsifying. (polyamines)

ADDITIVES USED IN I.L.B:

ILB of MAL is generally

using the following additives.

Viscosity index

improver:

It is prepared by the

blending of base oil (100 HVI) and an imported POLYMER. The viscosity of this

additive is 850 cst at 100 degree centigrade.

Infenium (calcium long chain alkyl salicylate):

Infenium has some types, which are used for lubricant

manufacturing i.e. infenium 1222, C9340, SV210.

INTRODUCTION TO BASE OILS:

The most important component of

lubricating oil is base oil. Base oil determines the flow characteristics of

lubricant, its oxidation stability (sludge and deposition tendency), its

volatility and corrosion potential.

Base oil from petroleum

consists of complex mixtures of paraffins, naphthenes and aromatics. If

paraffin predominates the base stock is paraffinic, if naphthenes predominates

the base stock is naphthenic base stock.

The API has also stabilized

five base stock categories, classified according to saturate content, sulfur

content and viscosity index.

Base Oil categories

Paraffinic

Paraffinic base oils are made from crude oils that have

relatively high alkane contents. The manufacturing process requires aromatics

removal.

Paraffinic base oils are characterized by their good

viscosity/temperature properties and good stability. They are frequently

referred as Solvent neutrals (SN).

Naphthenic

Naphthenic base oils are made from a more limited range of

crude oils than paraffinic. Important characteristics are low pour points,

because of wax free nature and excellent solvency power. Their

viscosity/temperature properties are inferior then paraffinic (low to medium

VI).

SYNTHETIC BASE OILS:

Synthetic base oils are

chemically derived, most often from ethylene gas, and contain none of the contaminants

present in mineral oils. Just as distilled water is pure water derived

from gas so synthetic base oils are pure oils derived from gas. e.g,

- Polyalphaolefins

- Alkylated aromatics

- Polybutenes

- Polyolesters

- Polyalkyleneglycols

GROUPS

|

% SATURATES

|

SULFUR CONTENT

|

VISCISTY INDEX

|

GROUP I

|

< 90%

|

> 0.05 %

|

80-120

|

GROUP II

|

>99%

|

< 15 PPM

|

100-115

|

GROUP III

|

>99%

|

< 15 PPM

|

120-140

|

GROUP IV

|

100%

|

0

|

120-140

|

GROUP V

|

the base stock

excluding group I,II,III and IV base stocks

|

||

BASE OIL USED IN

I.L.B:

NAME OF BASE OIL

|

VISCOSITY INDEX

|

VISCOSITY

(cst)

|

POUR POINT (°C)

|

FLASH POINT (°C)

|

COLOR

|

100 HVI

|

95

|

18.5-21 @ 40°C

|

-6

|

177

|

1.5

|

400N HVI

|

95

|

9.4-10.4 @ 100°C

|

-6

|

227

|

2.5

|

BS HVI

|

95

|

32-37 @ 100°C

|

-3

|

280

|

5

|

100N MVI

|

60

|

20-24 @ 40°C

|

-6

|

177

|

2

|

BS MVI

|

65

|

35-42 @ 100°C

|

-3

|

280

|

8

|

650 MVI

|

60

|

10.6-11.6 @ 100°C

|

-3

|

227

|

5.5

|

65N MVI

|

95

|

10-12 @ 40 °C

|

-9

|

130

|

1.5

|

150 HVI

|

95

|

28.5-32 @ 40 °C

|

-6

|

180

|

2

|

500N HVI

|

95

|

10.5-11.8 @ 100 °C

|

-6

|

227

|

3.5

|

CONSTRUCTION

OF STORAGE TANK

·

Stock in the bottom

cone of the tank is called DEAD STOCK.

·

The two holes one at

the top and the second at the side wall of the tank are called MANHOLE used for

cleaning of tanks.

·

There is a DIP MEASURING

HOLE used to measure the height of oil in the tank, this height is used to

measure the volume of oil in the tank.

·

DRAIN is used to drain

off the oil in the tank at the time of cleaning.

·

INLET AND OUTLET valve

are used to fill and empty the tank.

Below is

the list of the most commonly found additives in lubricating oil

Additive

|

Name

|

Characteristics

|

Detergency &

cleaning action

|

Phenaltes,Sulphonates,

Naphthenates

|

Interacts with varnish

or sludge to neutralize and solubilize.

|

Dispersant

|

PBI (Polyisobutylene)

Succinimides

|

Dispersants are

soluble in the oil and have a polar end which attracts and binds to

contaminants preventing settling and adhesion to metal surfaces.

|

Antifoaming

|

Silicone Polymers

(very low concentrations)

|

Not really necessary

for diesel engines in properly designed systems, but provides anti-foam in

gearbox and also at the refinery during blending.

|

Pour Point depressant

|

Polymethylacrylate

|

Used in SAE 30 grades

and below to ensure point criteria are met.

|

Anti-wear load

carrying

|

ZDTP (Zincdialkyldithiophosphate)ZDDP

(Zincdiethlydithiophosphate)

|

Chemicals react with

surfaces forming films which have slower shear strength than parent metal.

|

VI Improvers

|

Polymers of:

Methacrylate Acrylate Olefin Styrene-Butadiene

|

Increase in relative

viscosity more at high than low temperature.

|

Rust and corrosion

inhibition

|

Sulphates, Thiourea

type chemicals

|

Chemically absorbed

onto bare metal surfaces providing protection and neutralization.

|

Crude Oil Blending -

The commercial

driver for excellence

In-line blending of two

or more crude oils provides a major source of competitive advantage by

optimizing facility feedstock costs. However, if poorly executed, a

sub-standard blender design or configuration has been shown to result in blend

errors in excess of 2-5%, which can result in annual losses of over $7 million

- $15 million a year (for a 9mmtpa facility).

These losses can be avoided by using

companies specializing in complete blending systems (not just control systems)

to generate a detailed and achievable specification for a turnkey blender with

a performance guarantee early in the design stages. The successful

implementation of a crude oil blender hinges on consideration of the whole

process from site survey through design to planned blending operations. The

relatively small incremental cost of an optimally designed, bespoke blender,

compared with one of a sub-standard design shows a significantly improved

return on investment (ROI).

Introduction

The increasing

availability of lower cost heavy crude oil has driven investment in in-line

blending equipment to enhance flexibility and profitability. In-line blending

is a cost effective alternative to additional tanks and batch blending and

increases a facility's ability to process a wide range of crude oils.

Variation in crude

quality, tank layering, and inaccurate (or unknown) blend recipes combined with

poor blender design (hardware, software and integration), regularly cause blend

ratio errors of 2-5% or more unless blender hardware and control methodology

are optimized. For a 9mmtpa throughput facility with a nominal $39 bbl crude

price and a 10% discount for heavy crude, the spreadsheet below shows that at

least $7-$15 million savings can be made annually by reducing blend uncertainty.

Sources of error:

Error in crude oil

blending is derived from two main sources:-

1. Variation in

feedstock quality and blend recipes

2. Control system, field

equipment and system integration

Feedstock

and blend recipes

Crude oil stored in

tanks is rarely homogenous even with the use of tank mixers In addition, many

crude oils are blends and therefore the composition changes slightly from cargo

to cargo.

Blend recipes are often calculated using a

"typical" analysis and as a consequence the blend MUST use an excess

of the light (i.e. more expensive) crude, thereby exceeding the optimal ratio

to, ensure the process specification is met or exceeded. Errors in the blend recipe

model result in unnecessary "giveaway", which is directly

proportional to the inaccuracy in the recipe.

This variation in quality can be resolved

by using on-line analysers (viscosity, sulphur, density etc) to measure the

blended crude and provide a dynamic feedback signal; but, to be representative

the analyser system must be installed in a location that is homogenous and

representative at all process conditions and be correctly compensated to

standardised conditions. Representative analysis is one of the most important

factors in blender design.

Control system, field

equipment and integration

The heart of any in-line

blending system is the selection of the correct components, their integration

within the package and the performance guarantee of the total blending system.

Of vital importance to the success, and hence profitability, of an in-line

blender is how well the individual components perform AND how well they operate

once integrated in the blender with the control system.

Crude

Blender with remote control valves

Selection of appropriate blender components is the vital first

stage in ensuring the quality of the final blended product. Below are listed

some of the primary design considerations for key components;-

"Flow meters -

Turndown, suitability for crude, susceptibility to hydraulic noise

"

Control valves - Optimal control, stability and response time

without adverse pressure drop

" Mixing system - Pressure

drop, degree of mixing and range ability

" Control system -

Real-time three-term PID control, proven (i.e. not site-specific)

" Analyser system -

Location, noise, response time, flow weighting at standard conditions

Incorrect selection or

implementation of any of these components will result in fundamental system

errors that are likely to be impossible to resolve. Once selection is made, it

is vital to verify that the selected components are proven and can optimally

function for the full range of feed and blended crude oils.

One of the most common

errors when designing blending systems is a lack of attention to the critical

elements; it is risky to select components without understanding how they will

interact with each other, the control system and the dynamics of the site

environment. This can result in savings during CAPEX but never the optimal OPEX

and will therefore fail to deliver the best possible return on investment.

Case Study

Jiskoot has recently

supplied a system for blending heavy Mexican crude oil (13API) with lighter

(21-35API) crude. The system is a two-stream blender with on-line density

measurement designed to accurately produce a range of blend crudes from 16-21

API at up to 800,000 barrels per day.

Crude Oil Blender

Providing user-friendly

control, measurement and reporting of the whole blending process, the blend

controller uses on-line measurement to continually optimise final product

quality. Integration of the real-time blend control system with the facility's

Delta-V system enabled the facility to achieve a key objective of implementing

a 'maintenance on demand' system.

To guarantee accurate density measurement

and ensure that the final product is homogeneous a JetMix, power mixing system,

was used in the blend header.The JetMix is unique in that it mixes across a

wide range of flow rates and blend ratios with no pressure drop. This, along

with ultrasonic flow meters and careful component selection, allowed the

blender design to be optimised for a maximum pressure drop of less than 1.5bar.

The control system with flow-weighted

averaging and 3-term PID control ensures that the blended crude is on

specification at all times during the by batch using unique control algorithms

which respond instantly to changes in process conditions. The batch is

continuously measured and feedstock adjusted to optimise quality and minimise

'give-away'. The system is designed to ensure consistent blended crude quality

even during feedstock quality variations, starvation, loss of power or the

unlikely failure of a system component.

The system has been operational for over 12 months with the

customer stating:-

"The

Jiskoot blender …… is a vital component of our facility enabling us to cost

effectively and efficiently produce homogenous blended crude"

"The

blender has performed to our satisfaction and over the first four months of

operation has blended 37,000,000 barrels of crude oil"

It is clear that significant payback and

return on investment can be achieved if the correct technology is selected. The

key to success is to select and engage an engineering company specializing in

blending systems at an early stage in the project and ensure they are involved

in the complete scope of blending operations to maximize the value they bring

to the project.

If

correctly designed, installed and configured a blender can add significant

value to operations. If poorly designed and executed it can result in poor quality

blended product, potential revenue losses and plant downtime.

Mixing

and Analysis system

Lube Oil Blending –

An

Overview for Lube Plants

The blending of liquids and solids is an

art which goes back to the early Stone Age and in its simplest form could look

something like this.

From this we can move to

a more accurate method using a P.D. meter with ‘set-stop’ as shown here.

Supply lines

Set-stop

meter

Batch

blending

tank

Lube oil batch blending

by volume using single set-stop meter

Go a stage further and we can produce

batches using a weighing method such as shown below in which each ingredient is

discharged sequentially and weighed into the mixing tank (kettle).

Supply lines

Lube oil batch blending by weight using load cells

Another method is to use dedicated meters

to measure each component into a recycle-loop. This method is often called

‘stream blending’ and in the diagram below is shown with an additional in-line

dehydrator mounted in the loop

Another more

sophisticated approach is batch blending which is shown on the right. Batch

blending lube-oil in this manner is often called ‘cascade blending’.

If the blending plant

building height allows, cascade blending can produce very accurate batches,

very quickly with a minimal risk of contamination. Base components can be

metered/weighed into a ‘kettle’ before pre-mixing (cocktailing) which can be

flushed clean to avoid contamination.

Contamination is the

main concern of the lube-oil blender. Base products and additives are expensive

and mis-blending or contamination of the final product may mean down-grading

the product or using it to feed the burners. To avoid contamination it is

imperative that products are produced in ‘closely-related family groups’, or

entirely separately using different mixing tanks. Subsequent flushing and

efficient pigging are also essential tools to combat contamination.

In any of the previously

mentioned blending methods you take the ingredients to the mixing pot. When

this gets scaled-up, in a lube blending plant, it means that almost every one

of the base stocks and additives have to be available and measured at the

mixing/blending point. This involves a lot of piping, pumps, valves and hose

exchanges etc.

An alternative approach

is to take ‘the mixing pot to the ingredients’. Such a system can drastically

reduce the supply piping since the actual mixing vessels are transported, in

turn, to one or two points in the plant where all the base stocks and additives

are available through dedicated supply lines. Small volume additive metering

would normally be done by volume and large components either metered or

weighted (by placing the batch-tank on load cells). The batch tank is then

transported to a mixing station and eventually discharged after laboratory

checks, using a specialised system of conveyors and/or robots.

Lube

oil batch/weigh system

This type of system

(shown above) requires a purpose built plant and tends to limit the batch size

to about 5 tons, due to transport considerations. If used in conjunction with

load cells (with an accuracy/linearity of 0.04% over 10 to 1 range) the small

volume additives may have to pre-mixed by cocktailing or dilution before the

final process.

As you can see, batch

blending is not an instantaneous process. The sequential metering followed by

mixing and analysis can take several hours, depending on batch size and the

system employed. The picture below shows one of our lube batch blending plants

in which some of these mixing problems have been reduced by building the

blender around a Jiskoot Lube-Oil Dehydrator. The dehydrators’ recycling feature

allows the components and additives to be almost simultaneously metered into

the unit which then dehydrates and mixes them prior to discharge.

To summarize batch

blending, in its various shapes and guises, I believe that no lube-oil blending

plant can do without it, but I also believe that the constraints mentioned

early indicate the limitations.

An average/large

lube-oil blending plant will use 300 - 400 formulations/finished grades to

produce maybe 10,000 batches per annum. The majority of these will be small

with individual batch volumes rarely exceeding 2 -3 tons thus creating serious

contamination hazards. The special/high quality blend sector can account for 35

- 40% of annual tonnage. In today's high cost atmosphere special care and

attention in production planning is essential. This is the reason existing lube

blending plants have put greater emphasis on pigging lines, extra flushing and

installing dedicated metering lines etc.

A schematic of a typical

modern lube blending plant is shown at the top of the next page.

Production starts on the

left with the incoming base components and additives in storage tanks. The

additives usually require some pre-treatment such as heating, decanting or

maybe solids/waxes added. These are often cocktailed before being stored ready

for the blending process.

The base components may

be wet and require dehydration, which can be done with an in-line lube-oil

dehydrator, or heat and an air-sparger blowing in the stock tank (the latter can

take some hours).

The batch and in-line

blenders take these components and additives and turn them into the final

blended products that are discharged to storage,

Filling machines or dispatched

in bulk. The laboratory checks this entire process from start to finish

ensuring quality.

In-line

blending is a technique that any lube blending plant producing more than 20,000

TPA. Could use to great advantage.

In its very basic

schematic form an in-line blender looks like this.

|

||||

The advantages of such a

system are:

Lower production times and labour costs

through an almost immediate response to market demand (i.e. ‘you press a few

buttons’ and the final product is immediately available). No long mixing delays

and hold-ups in large tanks.

"

Better quality control, therefore reduced give-away because even

the smallest additive is metered accurately and dispersed evenly from start to

finish.

"

Reduced final blended product storage requirements therefore

saving on tankage, stock inventory, etc. - reduced capital lock-up.

Reduced labour

requirements - reduced floor area.

Whilst in-line blending

does offer many advantages, there will always be a place in a lube-oil plant

for batch blending facilities; if only because it is such a simple method with

excellent operational flexibility when it comes to smaller batch sizes. It

provides an almost infinite number of permutations of batch sizes and options

of metering/weighing and degree of automation etc.

Let us now look at some of the limitations of in-line blending:

•

There is an economical minimum size for an in-line lube blender

of approximately 60 - 80 GPM blend rate (16 -21 m3 /Hr). This is primarily

caused by the minimum acceptable size of commercially available flow meters for

metering additives at percentages as low as 0.1 - 0.2% of blend rate and the

general volume/area ratios of piping, strainer, meters etc. An in-line blender,

as opposed to a batch blender, relies heavily on meter range ability and this

tends to tail off with meters below 1/2".The employment of metering

pumps is often used for these low flow applications.

•

One normally only has 7 or 8 streams in an in-line blender. This

means that some planning is necessary to avoid the same metering stream being

used for non-compatible components in successive batches. However the lay-out

of a well designed lube blender means that one can adequately clear out piping

and strainers, etc.

As a consequence of

these limitations, we have adopted the following basic rules when consulted on

batch and in-line lube blenders for the ‘average’ plant.

1.

An in-line blender can be economically justified for an annual

production figure of 18,000 tones and over

2.

About 60% (plus) of total tonnage can normally be considered as

large batch (fast movers) and ideal for an in-line blender

3.

If there is a slight contamination hazard between successive

batches the batch size should not be smaller than the equivalent of 4-5 minutes

of the maximum blend rate (i.e. for a 100 GPM blender this would be 500

Gallons). This can be reduced for ‘family related’ blends. By inference

production planning should be governed by the compatibilities of successive

blends.

4.

Daily utilization of a typical in-line blender averages at

approximately 5 hours with a quality confidence of 99.9%.

The photo (right) show 3 blending systems

installed, to segregate feedlines, hydraulics, automation and industrial

products.

The photo below shows a

typical hose exchange, where the physical selection of base stocks and

additives with which this in-line blender is supplied takes place.

The last figure is a

schematic illustration of a lube plant I worked on a little while ago. The

system was designed to utilize as much of the existing plant as possible.

IN LINE BLENDING SYSTEM

In-line Blending In-line

Blending is the controlled, continuous mixing of a number of components to produce a

finished product of closely defined quality.

The quality of the

product is controlled as it is made. This is invaluable in continuous process

industries because the final product can be blended, analyzed and loaded in a

single process.

The alternative

Batch blending is the

main alternative. It involves sequentially introducing measured volumes of each

component into a tank. The components are then mixed, analysed for quality and

any adjustments made to the blend. This is time consuming and makes it

necessary to store both pre-blended and finished products. Nevertheless, for

small volumes and certain applications, this remains cost effective.

The specialists

Jiskoot is an internationally acknowledged

leader in the field of blending systems with over 40 years’ experience in the

design, manufacture and supply of customized turnkey measurement systems.

Jiskoot has supplied blending systems to many of the world’s major oil

companies and has a reputation for excellence and reliability. Our dedicated

engineering team is able to select the best measurement and control equipment

and design, manufacture, install and commission a turn-key blending system with

a performance guarantee.

In-line blending has many

advantages over batch blending.

Improved quality

The accuracy of an

in-line blending system is governed by the accuracy of the individual component

metering devices. Individual component accuracy better than 0.25% over the full Metering range can easily be achieved.

Faster blending

By performing analysis

and adjustment of the blend ratio on-line, the time consuming process of batch

metering, tank mixing, product analysis and blend adjustment is eliminated.

In-line blending greatly reduces process time, and provides a higher throughput

potential.

Greater flexibility

Changes in shipping schedules and product

specifications can be accommodated simply by selecting a different recipe from

the controller. As the blender operates in real-time, configuring a new recipe

is quick and easy in comparison with the planning and stock movement necessary

with batch blending. This allows you to offer a wide range of products and can

provide a valuable competitive edge.

Reduced storage and capital lock-up

In-line blending produces a finished

product almost instantaneously. It reduces the need for complicated production

planning and there is no need to hold stocks of blended product. An in-line blender

can feed products directly into road, rail or ocean tankers for shipment.

Cost optimization

Continuous

metering, closed loop control and higher accuracy provides better product

dispersion, better quality control and can substantially reduce the give-away

of expensive components and additives. Substantial savings can be achieved in

plants with a relatively low annual throughput

Reduced operating cost

Centralized control allows a single

operator to control several blending operations simultaneously. Once initiated

the blender will automatically produce the required final product.

Simplified plant layout

In-line blending enables a simplified plant

layout to be achieved. In existing plants this can free tanks, pumps and

pipelines for other duties and in new plants can considerably reduce capital

costs.

Lube oil blender

IN

LINE BLENDING

An in-line blending system comprises field

equipment and a control system.

Field equipment

The field equipment (valves, meters,

analyzers, etc.) enables the components to be simultaneously metered into the

‘blend header’ to produce the final product. Products

normally exit the blend header through a

mixer and can be analyzed to allow quality trim to be performed. In refineries,

the components can be taken directly from process units, avoiding or reducing

intermediate storage.

Control system

The control system monitors the outputs

from the field equipment (flow rates, etc), performs calculations for meter

linearization, temperature compensation, etc. and feeds back the appropriate

control signals to the field equipment to maintain the blending process within

the required parameters (i.e. closed-loop control).Blending control systems use

either real-time or PLC (ladder logic) technology. Jiskoot supplies either

technology depending on Crude oil blender

Application. . However, the cost,

response times and control provided by PLC technology has a number of

restrictions and Jiskoot also offers a multi-tasking real-time dedicated

blending controller, the Jiskoot InSight.

In-Line Blending

(Control

Systems)

Introduction

In-line blending is the

continuous mixing together of two or more different component streams in order

to obtain a final product of closely defined proportions. It is often more

economic than batch blending methods, saving money by blending faster,

requiring less manpower and storage facilities. An in-line blending system can

also be used to deliver the product directly into a pipeline or to road, rail

or ocean going tankers.

Jiskoot pioneered process automation

techniques and by taking advantage of the advances made in electronic design is

able to produce highly accurate blending control systems.

Basic Systems

In-line blending control

systems can be divided into two categories:

" Controlled

Rate Systems

" Flow Responsive

Systems

The blend rate of a controlled

blending system is governed by the demand flow rate set by the blend controller.

This can be manually or automatically controlled and all component flows are

maintained in the correct ratio, as a direct percentage of the total blend

rate.

The blend rate of a flow responsive system

is governed by the ‘Main’ or ‘Wild’ flow rate which is the main component

stream to which all components and/or additive flows are ratioed.

Each of these systems

has certain advantages. The flow responsive system is usually the cheaper;

however,

variations and options are available which provide considerable overlap in

control features and facilities of both methods.

The basic principle of operation of the

Jiskoot ‘controlled rate’ blender is that the flow in each component line is

measured by means of a flowmeter, and controlled (regulated) by means of either

a control valve, or by varying the output from a positive displacement pump.

The meter may be a

positive displacement meter fitted with a pulse transmitter, turbine meter

fitted with pick up coils, vortex meter, electromagnetic flowmeter or

‘Coriolis’ mass meter. The signals from these meters would be scaled and

totalized by the blender.

Flow responsive blender generates the demand flowrate for each

component stream. The demand flowrate is equal to the total blender throughput

multiplied by the required stream percentage. It follows, therefore, that by

varying the master demand rate the total blend rate is increased or decreased

without affecting the individual stream percentages.

The demand signal is fed

to each stream controller PID algorithm as a set point and compared to the

measured flow from the stream flowmeter. Any deviation between the set point

and the measured flowrate is stored in memory and an appropriate adjustment is

made automatically to the control valve in that stream. Thus opening or closing

the valve to increase or decrease the component flow to bring this back to the

required stream flowrate.

If there is starvation of flow in the

metering stream, the control valve will open to compensate, but if it reaches a

point at which it can no longer properly control, a cut-back (pacing) signal

reduces the demand rate to equal the maximum flowrate at which the lagging

component can maintain correct ratio and accuracy, and flags an alarm. If,

however, when the rate reduces below the minimum blend rate, the blockage in

the lagging component is still so great that control cannot be regained, a

signal will be automatically produced which shuts down the blender, and flags

an alarm. The amount of the lagging component that is missing is stored in the

controller memory, and on re-starting the blender after the component flow

restriction has been cleared, the component loss will quickly be made up and

the blend will continue with no loss of accuracy.

Similarly,

if the upstream pressure varies due to line size or tank head, the ability to

reach the required or set flow rate is sometimes lacking, in such a case the

system will “Cut back” the flow rate to ensure the product ratio is correct and

alarm to alert the operator. The systems are so designed to allow “cutback” to

continue until one of the streams reaches its low flow limit; at this point the

blender will be shut down as accurate flow measurement is not occurring.

In a flow responsive

system it is the main or wild component stream which is used as the master and

the other components or additives are ratioed to it, and are expressed as a

percentage of the main/wild stream.

Control System Accuracy

As the whole system is digital and

closed-loop, the accuracy of the electronics should be ±1 pulse for the flow signal,

and analogue conversion for temperature is around 1 part in 8000 for the 4-2ØmA

range. The control system accuracy therefore is as good as the accuracy of the

field equipment.

Since

one pulse represents a very small quantity, the control system is continually

calculating the so-called integral error between the required volume and the

actual volume. This “error” is transmitted as a change to the control valve

signal.

The accuracy of the

whole system will depend entirely on the accuracy of the flow meter used. This

means, therefore, that we can volumetrically blend components to within ±0.5%

of instantaneous flow rate.

It follows that if one

knows the quality parameters of the base components and additives, one can

produce a very good final product within very close quality parameters. Most

blending systems, particularly those in the petrochemical industries, operate

this way and produce very good results.

Analyzer Feedback and

Trim

There are occasions were

the quality of the base components of a blend may vary and yet it is still

required to produce a final product to close viscosity tolerances. The solution

is really quite simple: we use an analyser in the final blend header and

allowed the analyser signal a limited freedom to reset the volumetric ratio

setting. Jiskoot has used feedback signals from density analysers, viscosity

analysers

RVP analysers &

octane analysers.

It is important that consideration is given

to the effect of analyser trim, and the possibilities of stream starvation to

maintain quality. It is usual to allow only a small drift in quality adjustment

before raising an alarm; this prevents the analyser controls from shutting the

blender down completely due to a fault in the analyser.

This practice of “analyser feedback” is now

a regular occurrence in many multistream applications and it works very well.

However the specifications governing the sale of products are becoming much

tighter and the product costs are so high that many more quality limits are

introduced. For instance, fuel oil at one time was primarily sold on viscosity

only. In many cases this involved a simple two component blender that ratioed gas oil to fuel oil.

Today viscosity is not the only parameter looked at, some or all of the

following may also be controlled, sulphur content, pour point, density,

viscosity or the cetane no. for diesel oil.

It follows that the

production of fuel oil is no longer a simple two component blend. Indeed it may

be a four or five component blend and here we have a slight problem. To adjust

an accurate, volumetric flow proportioning device by means of a signal from an

analyser does not present a problem. To do likewise with signals from two

analysers may still be an acceptable solution, however, one can readily

visualise the “pushing-pulling” which could occur if quality parameters were

being adjusted which affected each other.

To cope with this problem a system known as

a non-interactive blending was designed, non-interactive in the sense that the

correction signals from the various analysers are employed in such a way that

they do not interact with each other.

However this form of

blending requires numerous analysers and a computer with the ability to handle

numerous complex calculations (matrix inversion).We are able to offer suitable

software packages to provide this facility together with ‘Blend Optimisation’.

Computer Supervised

Blending

This consists primarily

of a basic multi-stream blending system. However, all information such as

component percentages, totaliser, etc are interfaced with a computer, as also

is all analyser data. The function of the computer is as follows:

The PC is not used as a

blender, but as an interface between our controller which is capable of

handling all the field inputs/outputs and specific software for blending,

analyser trim, PID control of valves and valve/pump sequencing. In this

solution a typical PC is used in addition to our dedicated controller. The PC

also provides communication not only to the stream controllers but to other

Plant computers or DCS and SCADA systems in the plant or office.

The above configuration

allows the system to be totally distributed, the PC is used only for mass data

storage and a means for a control room operator interface, the blend control is

by stand alone self contained controller. This allows real time control and

processing with the added advantage that should the communications link fail

between the PC and the blender, the blending process will continue.

Equipment Selection

As

can be realised the mechanical components of the system are virtually identical

no matter which level of control system is chosen.

The

design of the mechanical section requires certain information to be made

available. As a minimum this information should be:

•

Expected overall system flowrate

•

Number of components required to make product.

•

Approximate ratios of each component.

•

S.G. of each component.

• Viscosity of each

component at normal blending temperature.

•

Minimum and maximum temperatures and pressures of each

component.

•

Expected batch sizes.

•

Number of recipes.

•

Whether an analyser is required and which type.

•

Whether those connections are made or the inlets permanently

piped.

To

this end we can supply blender questionnaires to assist in obtaining the

necessary information and to act as a reminder.

Jiskoot has in line

blending plants installed over twenty years ago still in operation with the

initial equipment, thus good engineering design coupled with correct equipment

selection is imperative.

Field Equipment

The basic elements

employed in each loop of a good in-line blending system are: